December 2024 - ID 4206 Wayne Li

Interdisciplinary (ID/ ME) Capstone Design - ID 4081

Create an Agrivoltaic System for grape farmers in The West Bank, Palestine. Capstone project with Jemma Siegel, Jonathan Choi, Savannah Luney, Ciera Hudson, and Akash Chennuri.

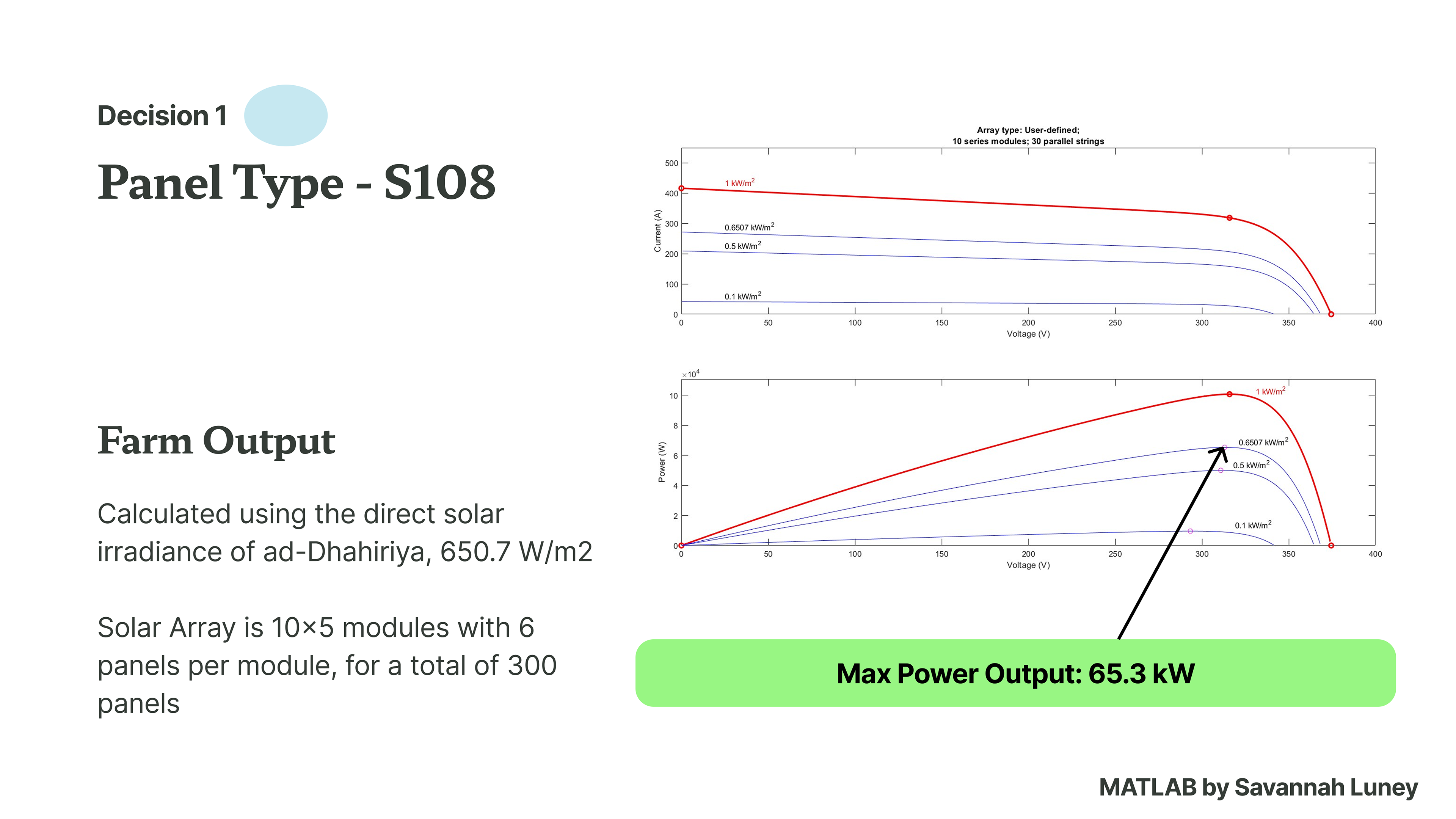

Palestine's growing temperatures are killing vineyards in the West Bank. Meanwhile, most of their power is imported, with over 50% reliant on Israel. We were able to design a solar panel shading system with vineyard families that generates over 65 KWH, providing economic security, and increasing crop quality by 30%.

This project was a collaboration between Georgia Tech and Palestine Polytechnic University. We were sponsored by The Department of State and The United States Agency for International Development.

My main contributions include co-leading the design team, leading a translation team with Palestine Polytechnic University, leading our user testing, creating a focused Value Proposition, and implementing it along with DFA and DFM principles into the final model.

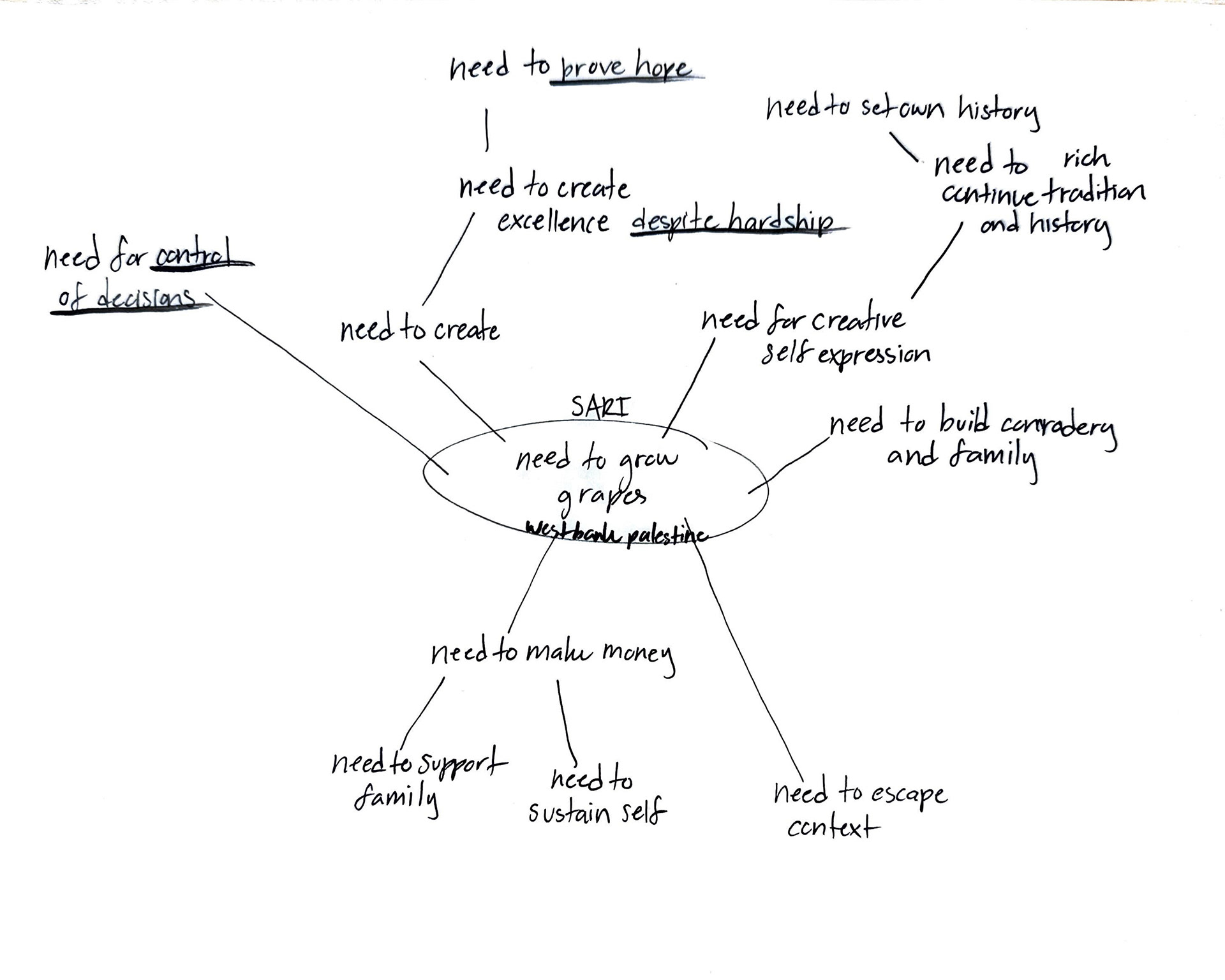

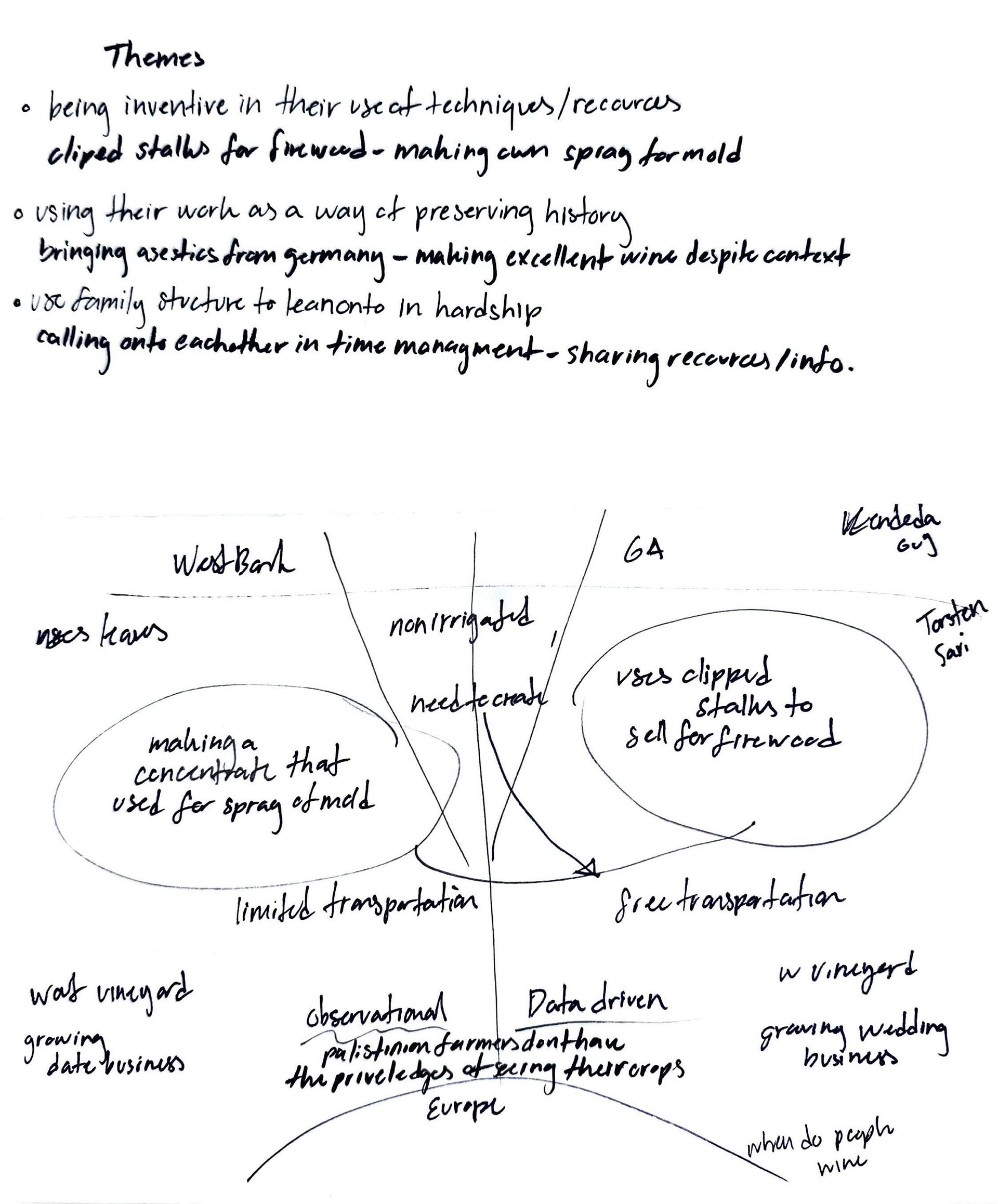

Process - Need-finding Phase

I created a journey map of the harvest cycle to determine opportunities for growth, as well as a shading and ripeing cycle to make sure our design fits within a system.

My ripening cycle findings showed us that most farmers only change the shade values on their vines twice in a harvest year.

Concept/ Prototype Development

This project was co-designed with 5 Palestine Polytechnic University renewable energy engineers: Lequa'a Awayssa, Yumna Allami, Saja Sharaha, Layan Al Herbawi, and Ibrahem Shrouf

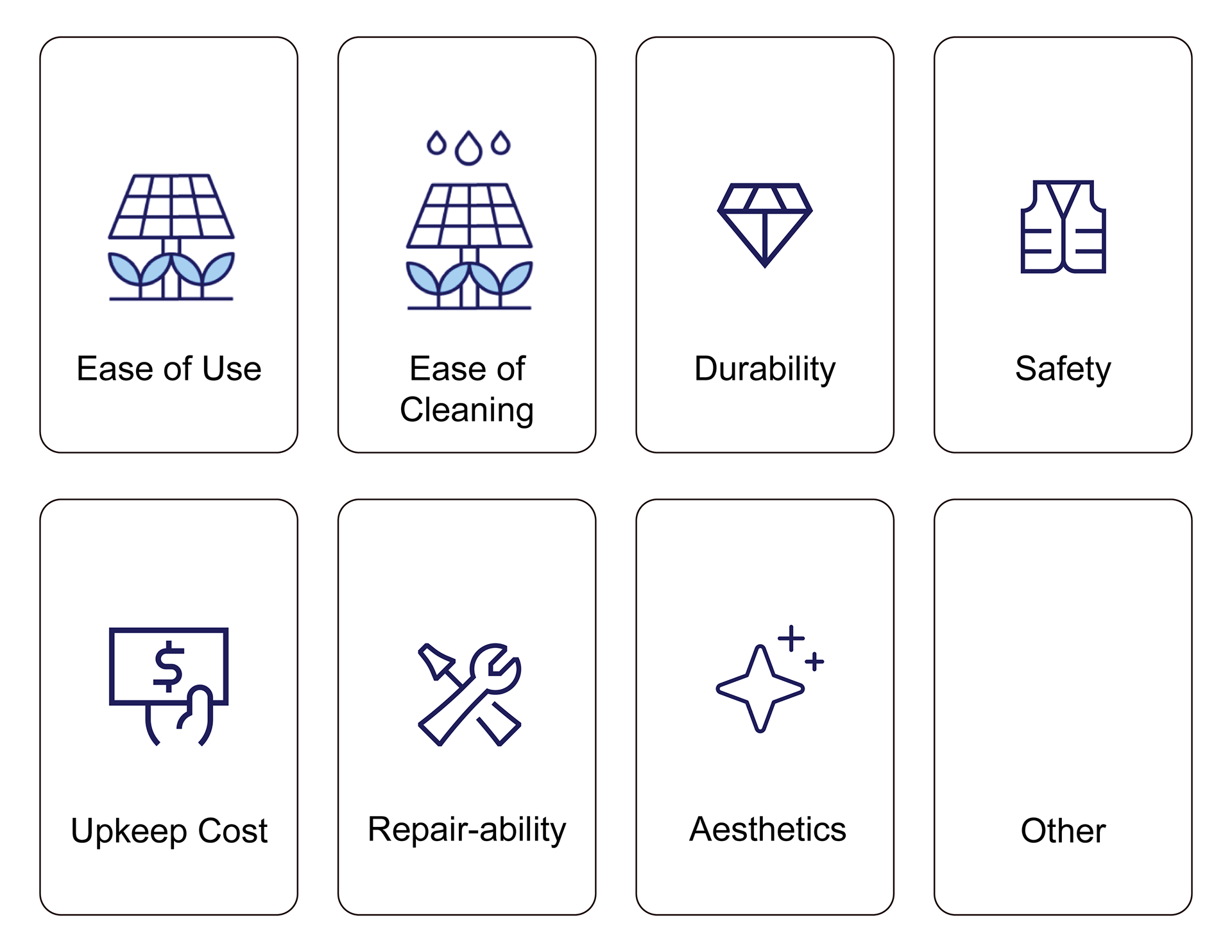

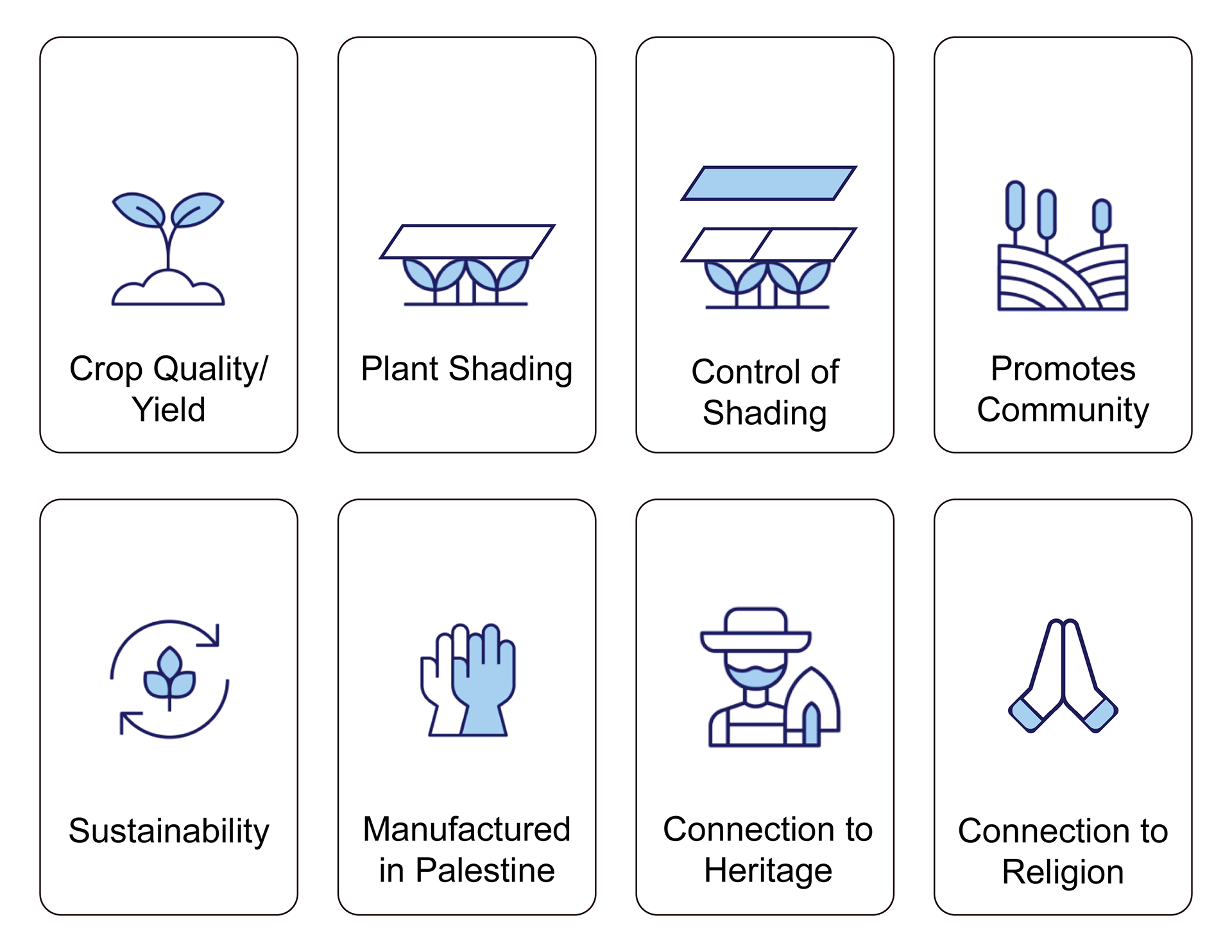

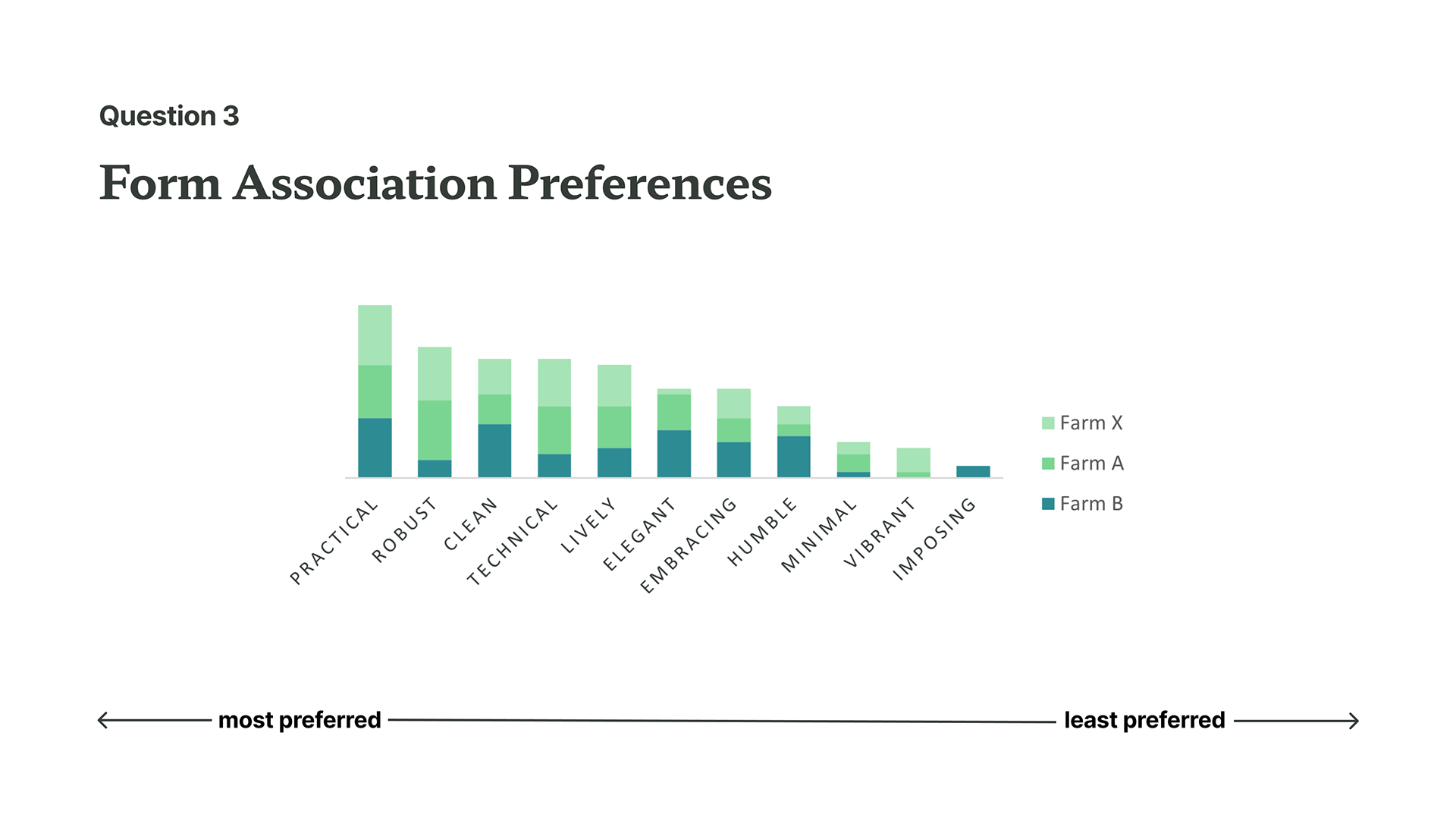

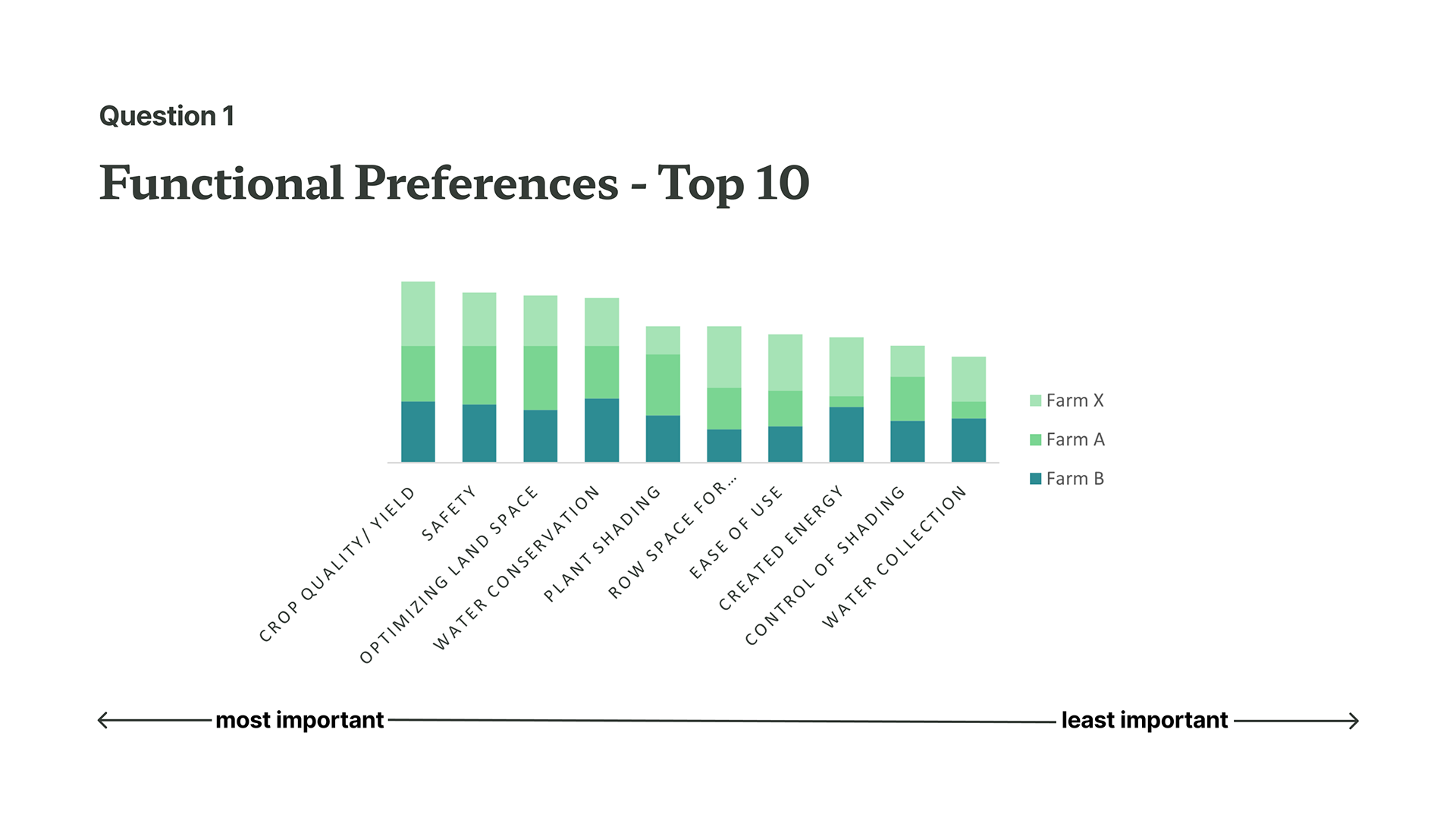

I conducted a card sort with this team to help us gain quantitative and qualitative results on our farmer's priorities for a more human-centric design.

Farms prioritized their crop quality unanimously.

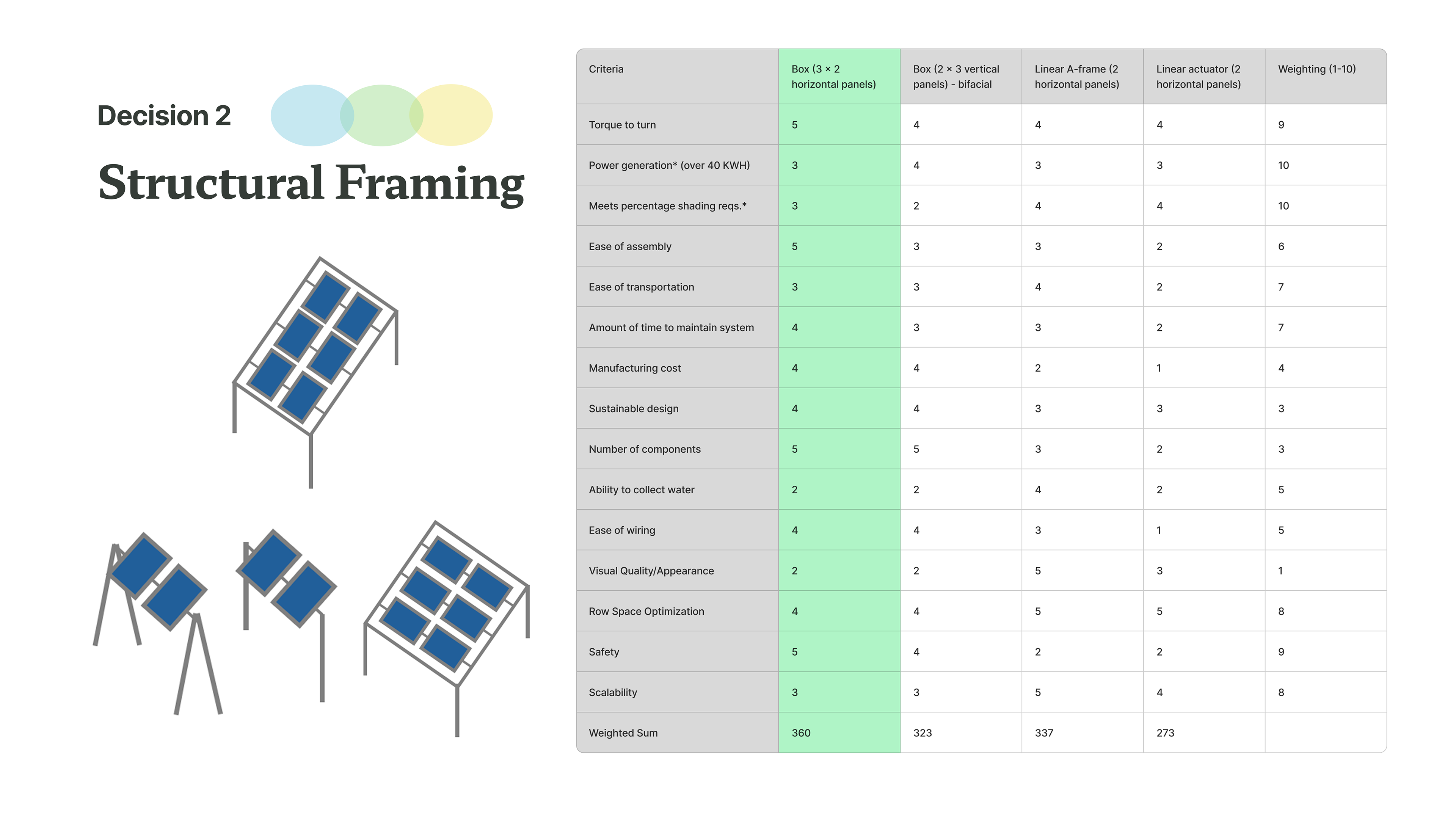

These preferences, along with customer requirements, research insights, and other stakeholder/grant requirements, helped me create a map of evaluation methods and a value proposition to give to our mechanical engineering team.

When we finished finalizing the Value Proposition, I realized we needed to consider both the framer and the Grant requirements of our system, catering to two audiences at once.

Concepts were divided into subsystems and evaluated using our criteria and value proposition.

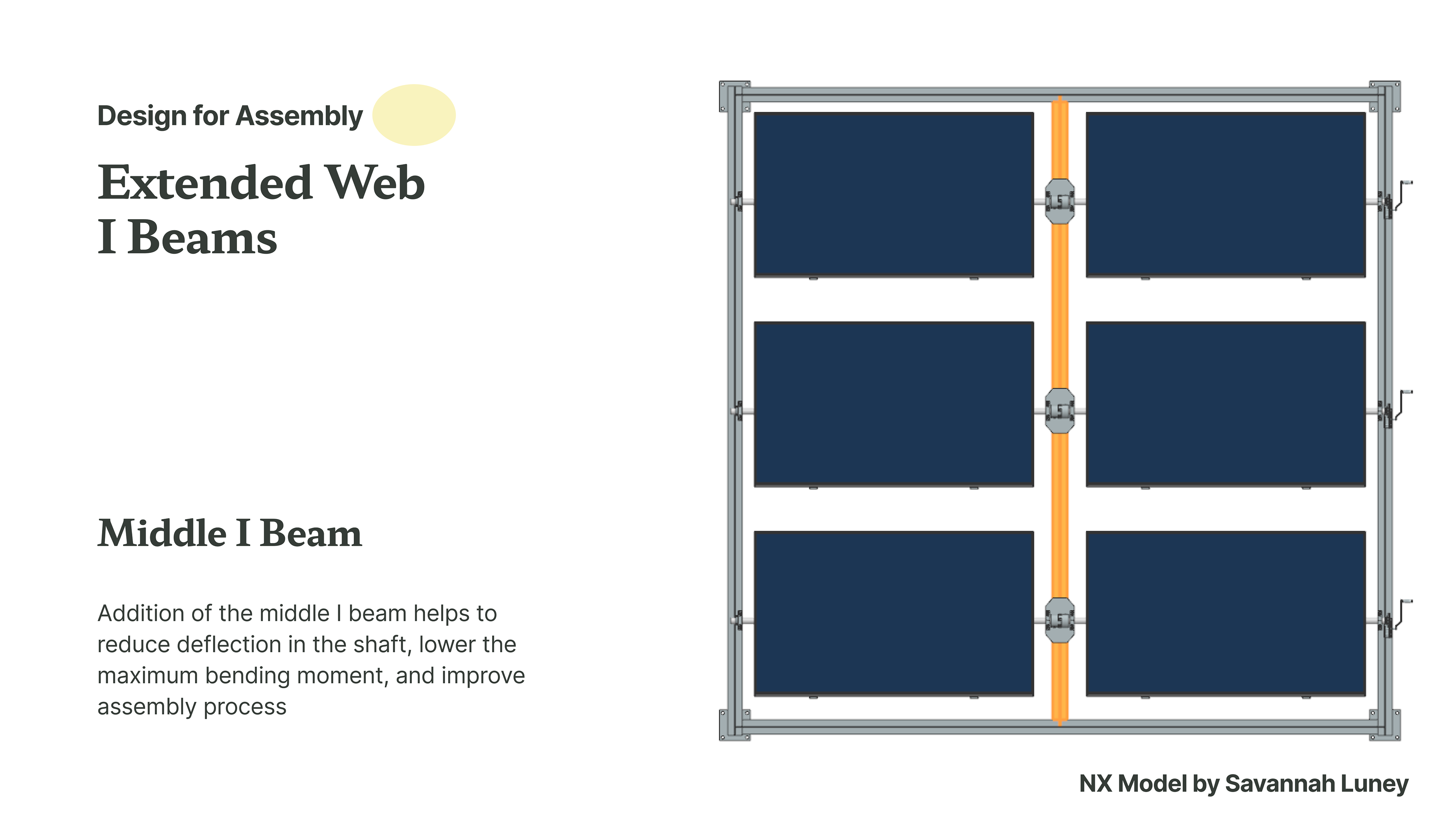

Along with Ceria Hudson, I created a 1/8 scale model to prototype and assess our DFA standards. One of our criteria was to design an assembly within the limit of 2 farmers.

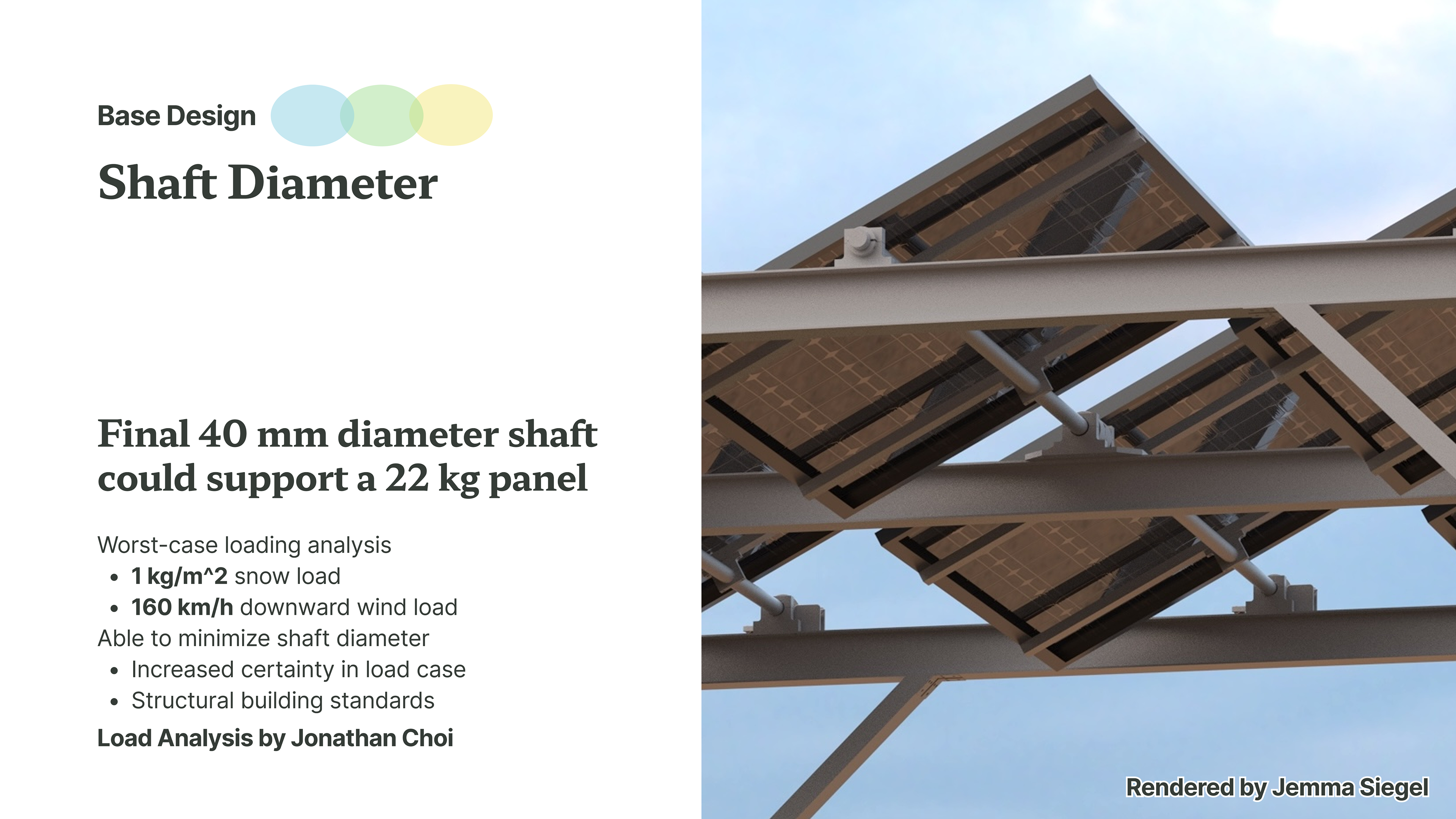

The final system took full advantage of what we learned, combining needs for assembly with maintenance, crop quality, and economic return.

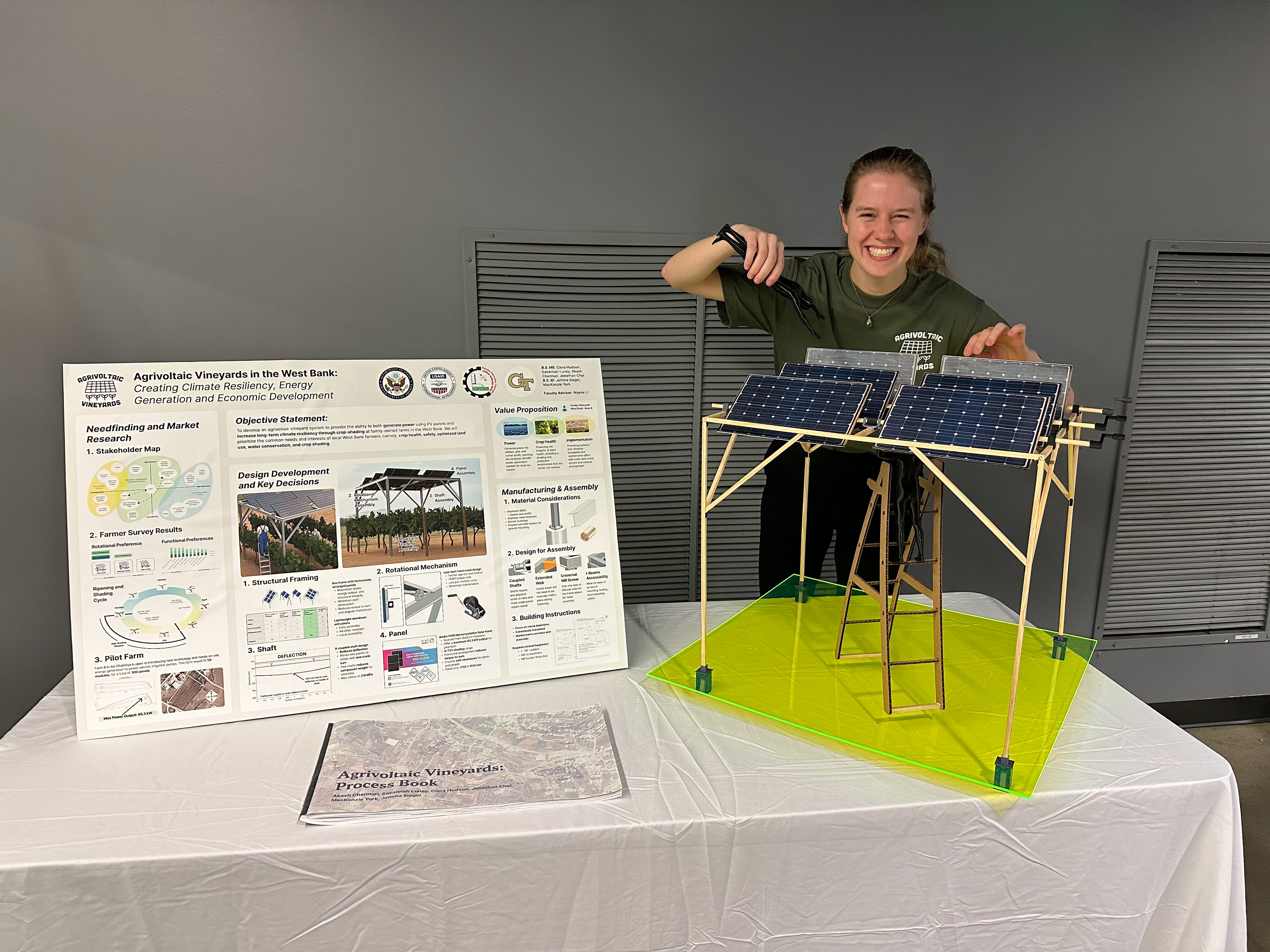

Built and presented a final prototype for the Georgia Tech Design Expo, creating a 1/12 scale model for reference to our life-size working crank model.

Reflecting on our final system, we compared it directly to our value proposition in order to submit this project to a grant funded by The United States Agency for International Development. (Dec. 2024)